|

กก |

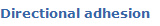

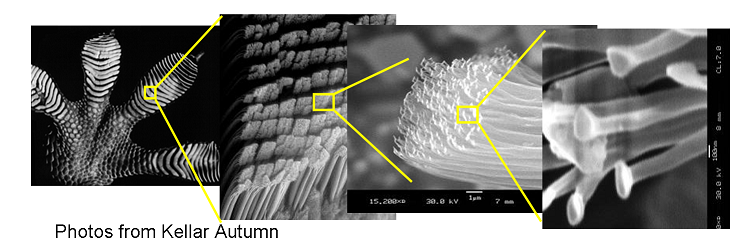

What is Directional Adhesive (Gecko

Tape)?

Directional

adhesion is a new innovation resulted from years of learning

from gecko's multi-hierarchical nano dry adhesive structures

as well as pondering about 'Stickiness'. It has Anisotropic

structure featured controllable adhesion with

directionality in adhesion force. The

movie

clip demonstrates directional adhesion

compared to conventional double sided tape. Unlike

conventional tape, it sticks on smooth surface with very

small preload and is also able to detach with by

reducing load. If it is loaded in desired

direction, it creates maximum contact minimizing stress

concentration along the contact area. if it is loaded in

wrong direction, the adhesion force is very low. (This

capability is also in contrast to the isotropic materials

using microfibers,

nanotubes, etc. that a number of researchers have been

developing.- Prof. Cutkosky) Directional

adhesion is a new innovation resulted from years of learning

from gecko's multi-hierarchical nano dry adhesive structures

as well as pondering about 'Stickiness'. It has Anisotropic

structure featured controllable adhesion with

directionality in adhesion force. The

movie

clip demonstrates directional adhesion

compared to conventional double sided tape. Unlike

conventional tape, it sticks on smooth surface with very

small preload and is also able to detach with by

reducing load. If it is loaded in desired

direction, it creates maximum contact minimizing stress

concentration along the contact area. if it is loaded in

wrong direction, the adhesion force is very low. (This

capability is also in contrast to the isotropic materials

using microfibers,

nanotubes, etc. that a number of researchers have been

developing.- Prof. Cutkosky)

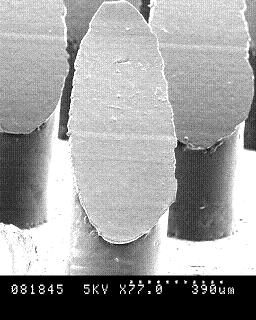

This

directional adhesive allows Stickybot to climb a range of

smooth surfaces like glass, acrylic and ceramic tile with

relatively fast speed. For a climbing robot, the role of

controllable adhesive is essential primarily because

light-weight of robot limits the maximum torque that

actuators can produce. First version was made in Sept.

2005. I did not understand essentials of adhesion and it had

very low adhesion. Alternations between design iterations

and better understanding about adhesion leads to current

design turned out to be successful. Directional adhesive is

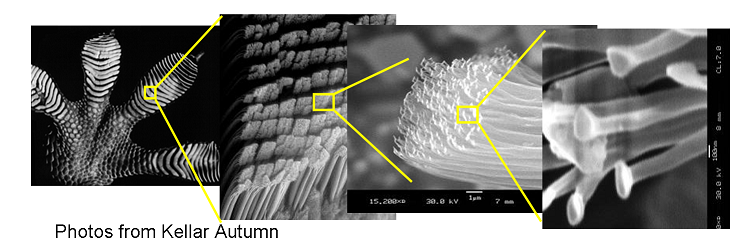

directly inspired by the work of

Prof. Kellar Autumn on gecko adhesion.

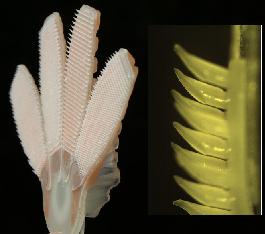

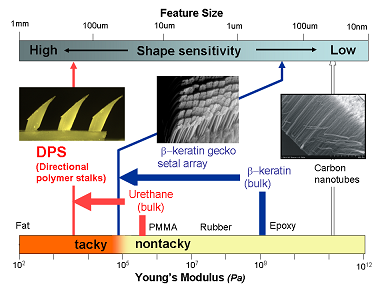

It can clean without any additional process and has

directionality in its adhesion. Figure I shows the range of

adhesive solutions ordered in terms of feature size and

effective modulus. A material is considered tacky when the

effective modulus is less than 100kPa (Dahlquist Criterion).

Using higher modulus material which is not tacky , the

hierarchical geometry of the gecko dry adhesive lowers the

effective stiffness enough to make the system function like

a tacky material. Same principle has been adapted on

Gecko tape (Directional polymer adhesion).

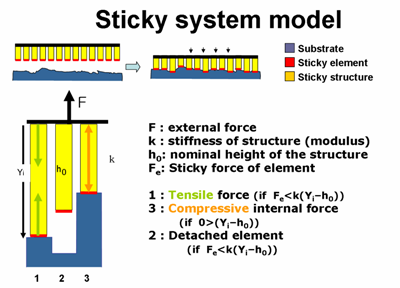

Adhesion system

model (What is stickiness?)

Many people asked me about

what kind of material do I use for sticky pads. As I

learned more about molecular mechanics, however, it is

getting more convincing to me that Adhesion is depends

more on geometry of structures than the type of material.

This is also consistent with literature. In the beginning of RiSE (Robots in Scansorial Environment)

project, winter of 2003, I was wondering about the reason

how sticky material can stick on surfaces. What feature

makes things sticky? My hypothesis was that the more

compliant the structure of a system, the stickier it is. I

came up with simple idea to test my hypothesis. Which is

very simple Adhesion system model that I made in Jan

2004.

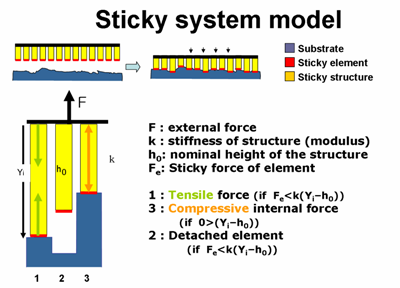

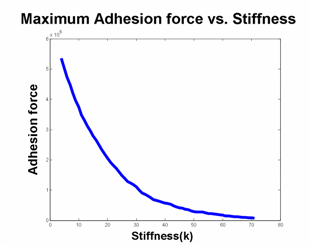

Bottom line question is

'what is

direct correlation between stiffness of the material and the

overall sticky force'. In the figure above, yellow bar

represents linear spring and red tip presents sticky

elements that remain in contact if pulling force caused by

deformation of sticky structure (yellow). After engaging

every single element on substrate, we can measure the

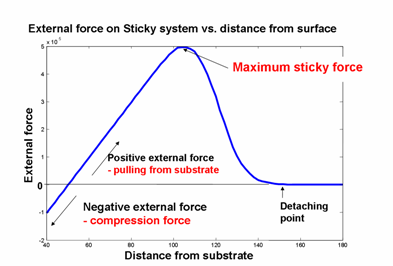

contact

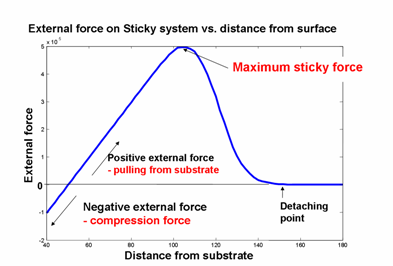

force

increasing distance from substrate (see blue curve in graph

above). It reaches a peak when the amount of force lost my

detached elements and the amount of force gained by

stretched structures. After this peak overall adhesion force

decreases rapidly and

reaches zero when all element are detached. We can measure

maximum adhesion force at a certain condition (substrate

roughness, structure stiffness, adhesion force of element). force

increasing distance from substrate (see blue curve in graph

above). It reaches a peak when the amount of force lost my

detached elements and the amount of force gained by

stretched structures. After this peak overall adhesion force

decreases rapidly and

reaches zero when all element are detached. We can measure

maximum adhesion force at a certain condition (substrate

roughness, structure stiffness, adhesion force of element).

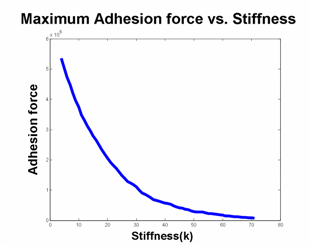

An interesting result yielded

from this simulation is that, with same sticky element, as

the stiffness of the structure increases, maximum adhesion

force drops drastically. This concludes that softer material

fundamentally stickier than stiffer material with same

stickiness of lower level elements. We can apply this

concept to each level of hierarchical system. I apply this

intuition on directional adhesive design.

กก

|

force

increasing distance from substrate (see blue curve in graph

above). It reaches a peak when the amount of force lost my

detached elements and the amount of force gained by

stretched structures. After this peak overall adhesion force

decreases rapidly and

reaches zero when all element are detached. We can measure

maximum adhesion force at a certain condition (substrate

roughness, structure stiffness, adhesion force of element).

force

increasing distance from substrate (see blue curve in graph

above). It reaches a peak when the amount of force lost my

detached elements and the amount of force gained by

stretched structures. After this peak overall adhesion force

decreases rapidly and

reaches zero when all element are detached. We can measure

maximum adhesion force at a certain condition (substrate

roughness, structure stiffness, adhesion force of element).